DW Series Multi-layer Mesh-Belt Dryer

- Model:DW Series

- Categories:Dryer Series

- Email : contact@he-mu.com

| Parameter | 单位 Unit | DW₃-1.2-8 | DW₃-1.2-10 | DW₃-1.6-8 | DW₃-1.6-10 | DW₃-2-8 | DW₃-2-10 |

| Unit number | 4×3 | 5×3 | 4×3 | 5×3 | 4×3 | 5×3 | |

| Drying section length | m | 24 | 30 | 24 | 30 | 24 | 30 |

| Thickness of the material | mm | 10~80 | |||||

| Temperature | °C | 50~140 | |||||

| Steam pressure | Mpa | 0.2~0.8 | |||||

| Steam consumption | kg/h | 360~600 | 420~720 | 450~840 | 480~960 | 480~960 | 630~1350 |

| Area of heat exchange | m² | 816 | 1020 | 1056 | 1320 | 1344 | 1680 |

| Drying strength | kgH₂O/h | 150~450 | 220~550 | 240~600 | 280~750 | 280~750 | 350~900 |

| Power equipment inside | kW | 30.8 | 37.4 | 42 | 51 | 56 | 68 |

| Power equipment outside | kW | 35.3 | 41.9 | 46.5 | 55.5 | 60.5 | 72.5 |

| Overall dimensions | m | 9.77×2.2×4.5 | 11.77×2.2×4.5 | 9.77×2.6×4.5 | 11.77×2.6×4.7 | 9.77×3.06×4.9 | 11.77×3.06×4.9 |

| Weight | Kg | 4800×3 | 5780×3 | 5400×3 | 6550×3 | 6350×3 | 7800×3 |

Product introduction

The belt drier is a continuous drying equipment in batch production. lt issuitable for drying the raw materials that is in the shape of piece, strip orgranule and is good in permeability. Particularly it is suitable for such rawmaterials that contain high moisture and are not permitted hightemperature for example, dehydrated vegetable, catalyst, drinking tabletof Chinese traditional medicine. Its features are fast in drying speed,strong in vaporization, good in quality of products. Typical products Dehydrated vegetable, granule feed, monosodiumglutamate, check extraction, organic pigment, synthetic rubber, propylenefiber, medicine, medical material, small wooden products, plastic products.aging or solidifying for electronic elements. For pasted raw material suchas filter cake, it can be dried after shaped through granulator or extruder.

Description

DW series many layers belt dryer is used in the material hard to dry andlow dry speed. The equipment structure is compact. lt covers small areawith easy operation,convenient maintain and steady running. Theequipment extend and promote the heat wind circle oven which designthe dryness process with different heat wind circle as per the drynesscharacteristics of materials. lt is widely used in chemical, metallurgyindustry, food, packaging.The dryer has lots of superiorities as highefficiency,saving energy,easy management, larger output, constantproduct and varied ability.

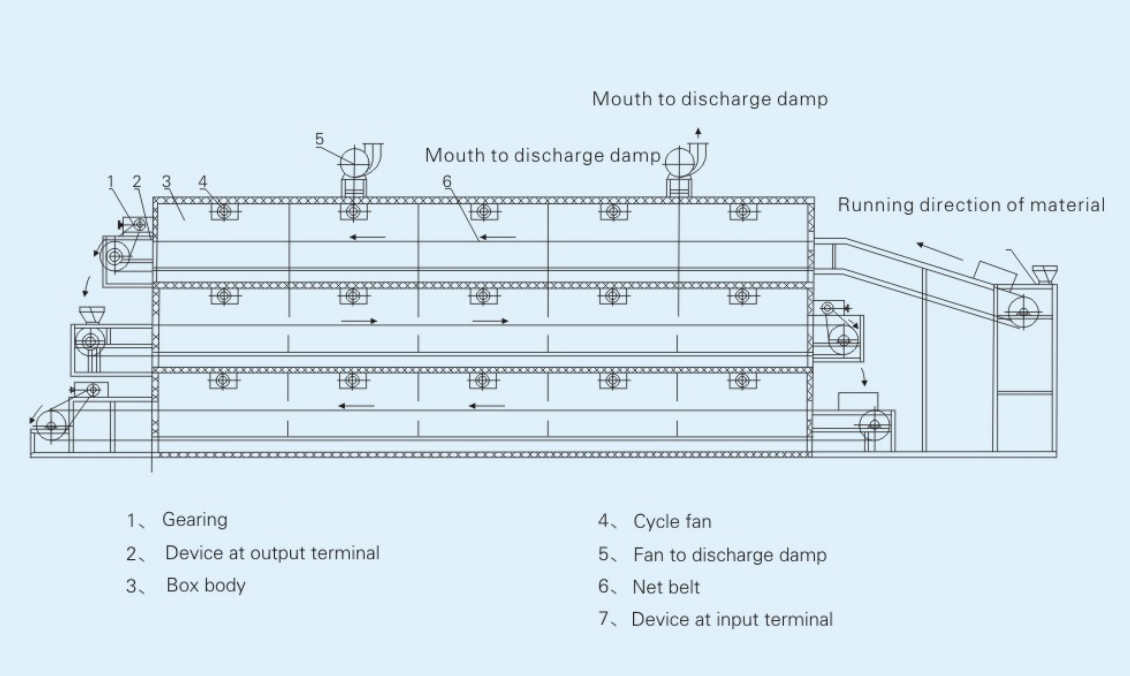

Schematic of stracture