DLY-125W1 Portable Metalworking Band Saw Machine

Cutting Capacity :

In this era of rapid industrial development, the fully automatic circular saw machine has become an indispensable and important equipment in many factories and workshops. It has won the favor of the majority of users with its high efficiency, precision and stability. However, during the long-term use of the fully automatic circular saw machine, the wear and replacement of the saw blade is an inevitable problem. So, how to change the saw blade of the fully automatic circular saw machine?

In fact, the replacement of the saw blade of the fully automatic circular saw machine is not a complicated matter. As long as you master the correct methods and steps, you can easily complete it. Before starting to replace the saw blade, we need to turn off the power of the fully automatic circular saw machine to ensure that the equipment is in a safe state. Next, you can follow the steps below:

1. Prepare tools and new saw blades

Before replacing the saw blade, we need to prepare the corresponding tools, such as wrenches, screwdrivers, etc. At the same time, make sure that the new saw blade is consistent with the original saw blade model and specifications to ensure the normal operation of the equipment.

2. Disassemble the old saw blade

Find the screws or buckles that fix the saw blade on the fully automatic circular saw machine and loosen them with a wrench or screwdriver. During the disassembly process, be careful not to damage the saw blade and other parts of the equipment. Gently remove the old saw blade from the equipment and set it aside for use.

3. Install the new saw blade

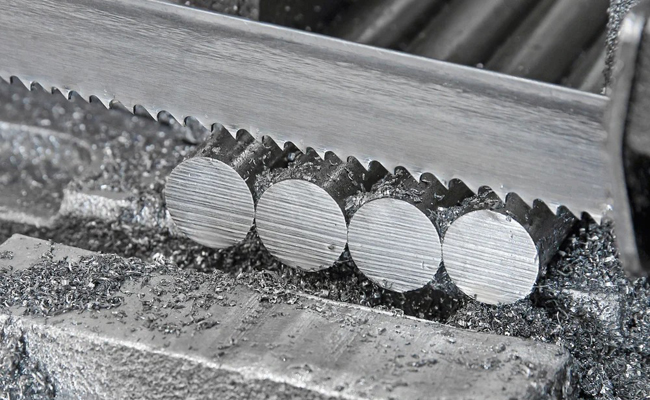

Align the new saw blade with the installation position of the fully automatic circular saw machine, and make sure that the tooth surface of the saw blade is consistent with the cutting direction of the equipment. Then, use a wrench or screwdriver to tighten the screws or buckles to fix the new saw blade. When tightening the screws or buckles, pay attention to moderate force, not too tight or too loose.

4. Check and adjust

After installing the new saw blade, we need to check and adjust the fully automatic circular saw machine. Check whether the saw blade is firmly installed without shaking or loosening. Then, start the equipment and observe the operation of the saw blade to ensure that the saw blade can cut the material steadily and smoothly. If the saw blade is found to have abnormal phenomena, such as vibration, noise, etc., it should be stopped immediately for inspection and adjustment.

5. Daily maintenance and care

In addition to regular replacement of saw blades, we also need to perform daily maintenance and care on the fully automatic circular saw machine. Regularly clean the dust and debris on the equipment to keep it clean and tidy. At the same time, regularly check the various parts of the equipment, such as motors, transmission devices, etc., to ensure their normal operation. In addition, attention should be paid to the lubrication and maintenance of the equipment, and lubricating oil and worn parts should be added in time to extend the service life of the equipment.

Regularly replacing worn saw blades can ensure the cutting accuracy and stability of the fully automatic circular saw machine, thereby improving production efficiency and product quality. Secondly, correct maintenance and care can extend the service life of the equipment and reduce the failure rate and maintenance cost of the equipment. By mastering the correct replacement methods and steps, we can avoid equipment damage and safety accidents caused by improper operation, so that the fully automatic circular saw machine can always maintain a good working condition and provide strong support for our production business.

Cutting Capacity :

Cutting Capacity :